5 Effective Supply Chain Planning Strategies

Alex

2/24/2022

Keep the flow of goods accurate and timely while maintaining the high availability of products is the job of supply chain planning. Put like that, it seems easy. Supply chain planning, however, is in no way easy. With multi-variant factors such as shipping speeds, costs adjustment, raw material availability, factory issues, and more it's no wonder big companies invest millions into their supply chain planning solutions. Since we don't cater to the largest of companies, we'll simplify things to make the most relevant suggestions for small and medium enterprises dealing with increased complexities in their supply chain planning process. The solutions here are intended to be interim processes that can ease the burden of not having a fully-fledged supply chain planning system on your path to growth.

Strategy #1: Best and Worst-Case Scenario Planning

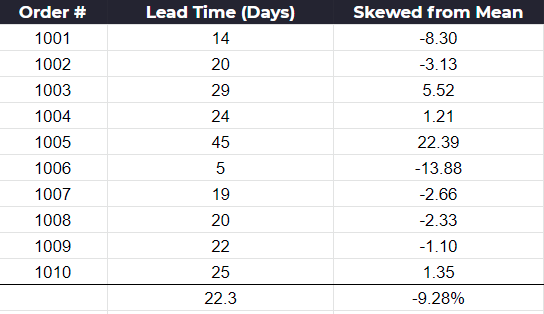

No matter how you are doing your supply chain planning of goods, you should always look at an extrapolation toward what might be the best and worst-case scenarios. For instance, using a best-case scenario how many days will it take your supplier to ship the goods and for them to be accepted at the warehouse? During the longest lead time, how long did this shipment take to arrive? Here is a simple way of improving the supply chain planning around vendor lead times. This simple table shows the average lead time over 10 orders. Using this, each individual order lead time is subtracted from the total average to get a variance from the mean. Averaging this value will give you an average variant percentage. In the example below the vendor usually would ship 9.28% faster than the average delivery time. This could be used to make earlier predictions on order times.

Strategy #2: Reserves for Top 20% Sellers

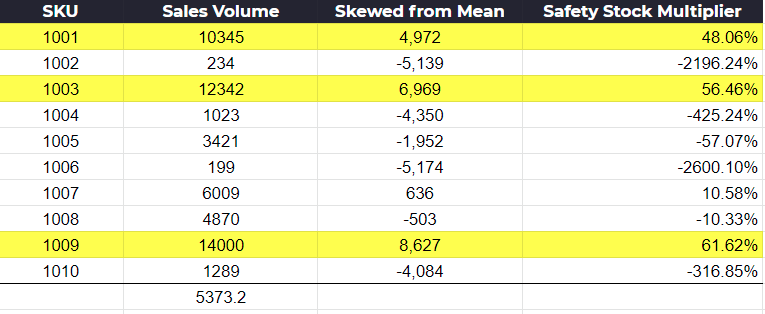

The all-important Pareto principle states that 80% of the outcome results from 20% of the inputs and 80% of the consequences result from 20% of the causes. In other words, your top 20% of products by sales volume are going to produce 80% of the revenue from your store. This principle holds true for almost everything in life and should be reserved for use in your business.

Make it easy on yourself (if you are using Shopify they already do this) to identify your top-selling items. For stores with a high SKU count, this can be harder to do and even more important. For these top 20% sales volume items, make sure you are catering purchasing to meet the demand. These items should always be allowed a higher backstock threshold since they are more likely to sell out and the inventory turnover is still high on these items. This simple table shows random items and their purchase volumes, with another column to show the number of units this product sells over/under the average sales volume of any product in the dataset. You could then use the variant percentage as a way to determine safety stock levels for this item.

Strategy #3: Construct a Days on Hand Table

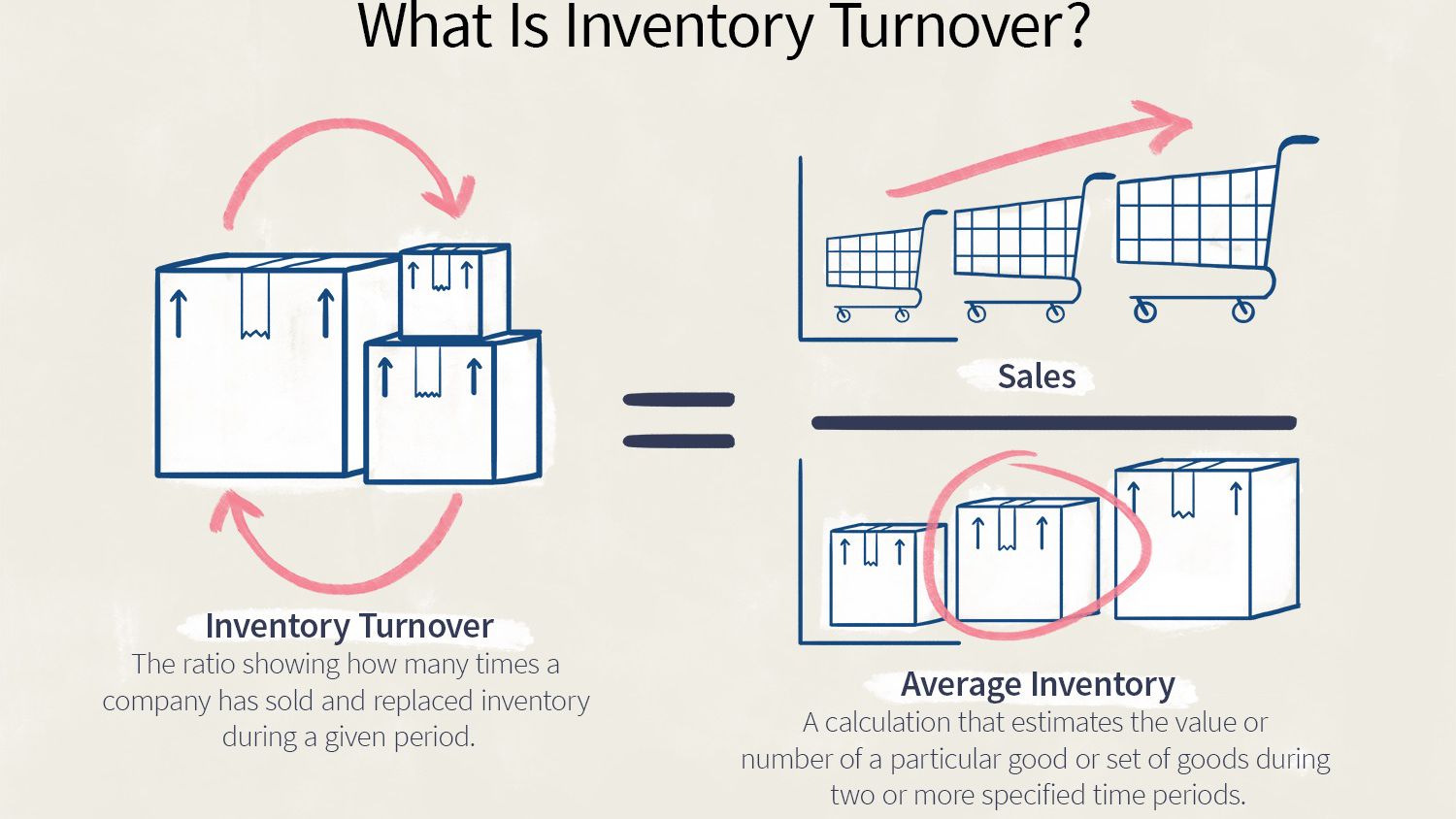

Another factor beyond lead time for inbound purchase orders is the days of stock on hand. This is a simple measure to understand, based on current volume, how many days of stock you have left before running out. It's important because this is a reliable measure for understanding where you stand on inventory. More complex models will use a moving average, and time comparison model for different periods. This becomes a bit cumbersome of a process when you are manually calculating this. The process is to export your orders, and inventory, then to cross-compare them to see based on current or moving average sales volume how many days you have left. When you combine this with lead time, you can get a pretty accurate measure of days on-hand inventory for any given item. SKUSavvy does this for you with a combination of lead-time and calculated on-hand stock when making purchase orders.

Strategy #4: Invest Early in Systems

It can be easy to overlook systems early because they may seem daunting or expensive. This can end up a critical mistake later. Though your inventory and fulfillment, website and marketing, customer support, and beyond might be more pressing, take time to learn about systems early on. Even if it's developing some excel models early on, and later trying out a Shopify app for purchasing. Becoming familiar with your own models for stock on hand, and how you derive benefit by using these, will enable a streamlined workflow down the road when you do invest in bigger systems.

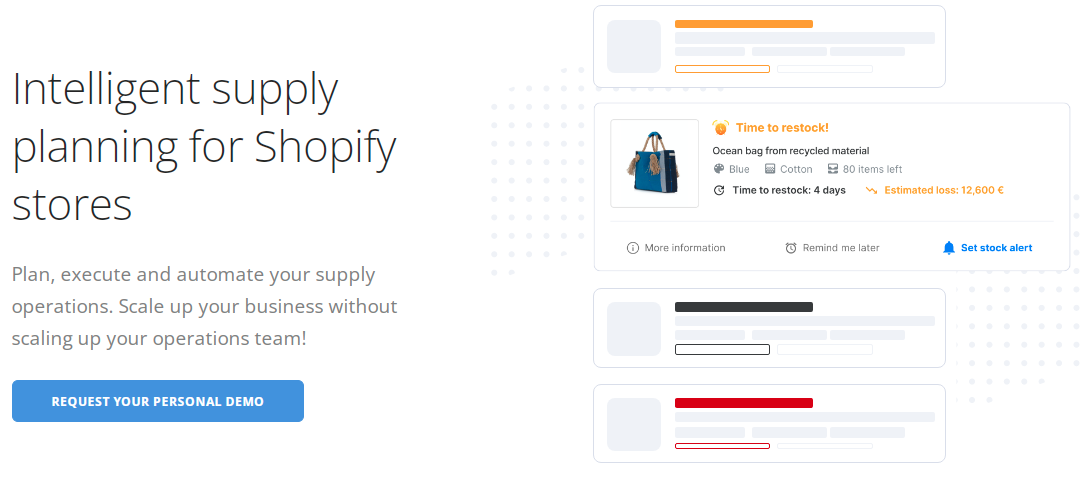

While SKUSavvy does offer some basics for supply chain planning we've partnered with Fabrikator to handle supply chain planning in a simple and effective Shopify app.

Check out Fabrikator for your Store

Strategy #5: Multiple Suppliers

When you source products, it's likely at some point there will be shortcomings in the availability. To overcome this, it's a good move to have multiple suppliers for as many of the items you carry. When you are having your product manufactured directly you can get quotes and shop around for other suppliers (assuming any legal obligations from contracts) as a backup. Some companies will go so far as to get samples and have the product made. Of course, this is costly and should be timely when it's done. For suppliers who do not meet your requirements for delivery timeliness, you can and should get quotes and start split ordering. This will help keep suppliers on the ball and makes sure you have redundancies in place. Going this extra mile step can sometimes be the least expensive formula for maximizing your supply chain effectiveness. As with any added complexity, this does make it more involved to purchase split orders. When using SKUSavvy, you can simply create two separate orders across suppliers. When it gets more complicated without a system is to compare leads times across vendors.

These simple tips can keep your business on track and in stock. Keeping stock up for customers is after all most important. Keep experimenting and coming up with methods that work for you. The holy grail of effective supply chain planning is to have multiple years of purchase and order volumes. Using this modern AI systems can combine various data sets to get highly predictable delivery and lead times, as well as days on hand.