Common Problems & Questions You'll Come Across in Shopify Inventory Management

Alex

1/30/2023

At some point or another along your Shopify path you'll come across a few challenges that will seem insurmountable because a solution is non-obvious. Seems to come up relating to Shopify inventory management quite frequently. People ask how they can split an order fulfillment across different locations, or why their on-hand and committed values to line up, or why a back-order is showing inventory available in one place and not the other. While many of these things are pretty easy to solve, some are quite challenging and may require the use of an app or software scripts to solve. For stores with simple operations procedures these challenges might not come up. For bigger stores looking to maximize the various customer requests upon you, these topics may come up all the time.

What are some common questions?

What is the difference between committed, available, and on-hand inventory values?

How should I handle orders fulfilled across different locations?

How are backorders treated in Shopify and how will this effect my inventory?

What should I do about bin locations for my inventory?

How should I handle rebalancing my inventory across locations?

Does Shopify help with reorder quantities?

How should I handle perishable items with Shopify inventory management?

These questions come up when you start doing bigger volume across multiple locations and across many different product SKUs that are allocated across both of your locations. Shopify has also introduced features to help sell across country boarders, but the operations stack for handling these complex scenarios have largely fallen upon the app store to manage those types of scenarios. So what do these questions mean, and how should you think about them when managing your store?

What is the difference between committed, available, and on-hand inventory values? And when will the inventory values change?

Until recently Shopify only provided an on-hand inventory value. Now there are three values to distinguish between stock that you actually have, and stock that is tied up because a sale was made or it is expected to arrive. These can certainly help you plan inventory and give a more accurate idea of what inventory is really available. So lets take a look at each of these values:

Committed Inventory

The inventory already allocated to orders (both outbound and transfer orders) is your committed inventory. This inventory should not be counted as part of any quantity to know what you have because it is assumed to be going out as part of an order. When planning for inventory purchasing you should exclude the committed inventory. When an order is cancelled, or part of the order is cancelled, the committed stock for that order should come back into the available stock count.

Available Inventory

This inventory is your total inventory count minus any committed inventory. This value should be used when calculating repurchase quantities of inventory since it is already omitting any stock planned to go out.

On-hand Inventory

The combination of committed value inventory and available inventory is your on-hand inventory. Because this value takes any item into consideration is should be used for when calculating your total inventory value as the commited inventory is still within the warehouse.

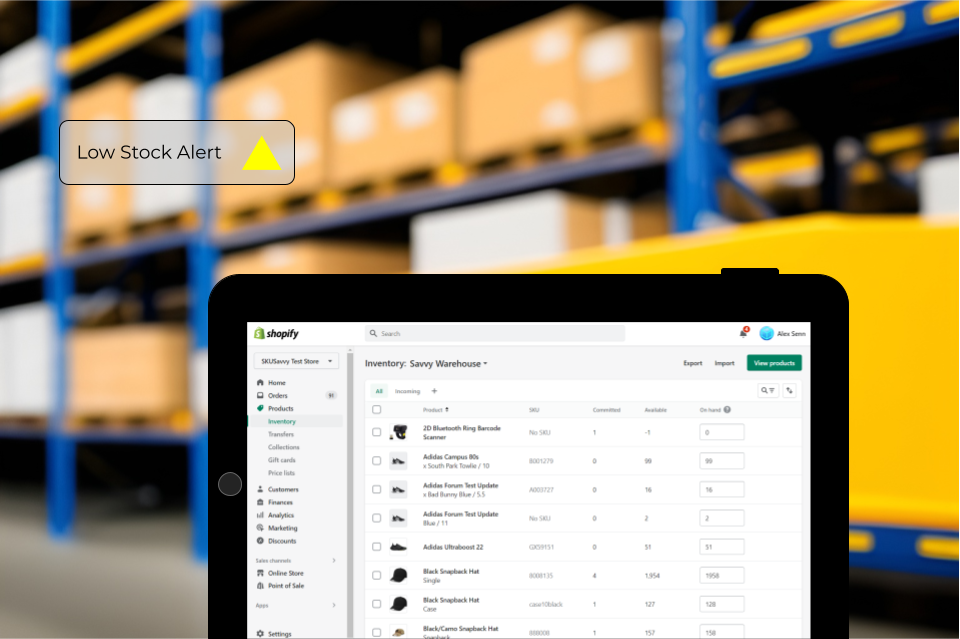

When it comes to your inventory system, you might find that the system will only use one value such as the on-hand inventory count. This is fine so long as the system has it's own method of subtracting out the committed stock and/or provides suggestions for inventory repurchase that include committed stock into the calculation. Shopify recently opened these inventory API endpoints so any system connecting with Shopify should be able to take them into consideration.SKUSavvy uses all three inventory states from Shopify

How should I handle orders fulfilled across different locations?

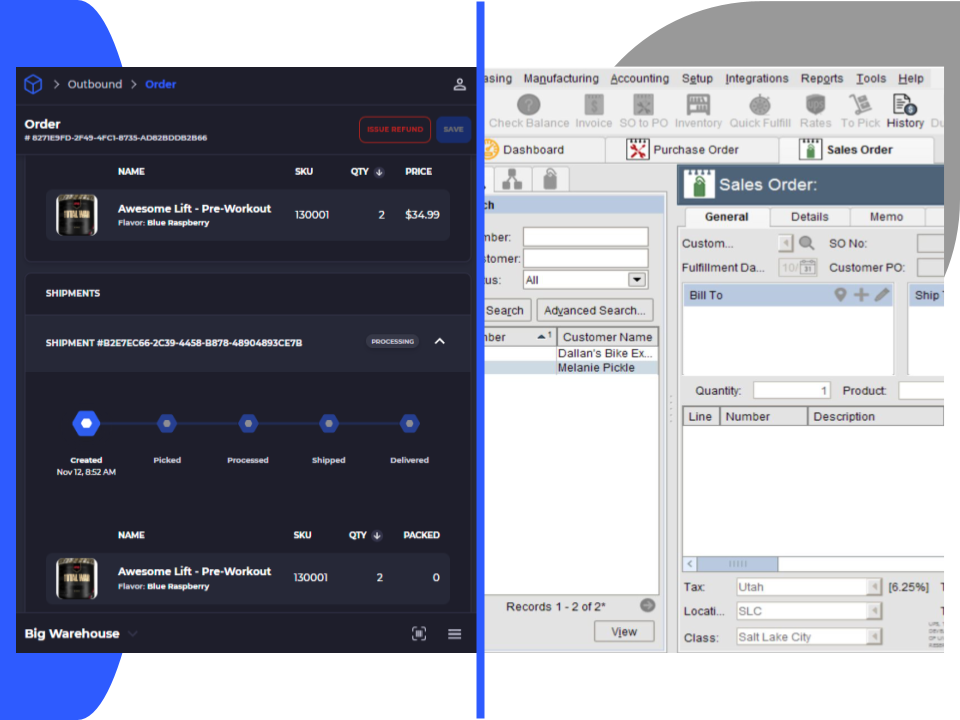

This is referred to as a split fulfillment and can be dealt with in a few different ways within Shopify. If using a warehouse management or inventory system you may find there are different paths to get the same result here. So, lets look at how you can handle this situation within Shopify.

Multi-location fulfillment

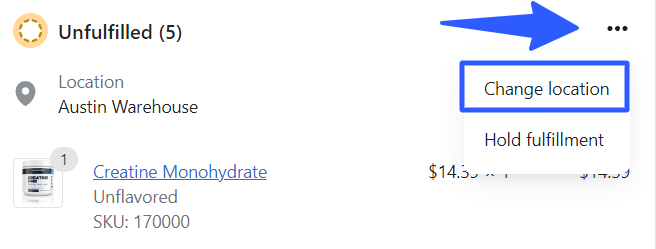

Stock inventory at two or more locations within Shopify. Fulfill part of one order directly in Shopify from location A, and transfer the unfulfilled portion of that order to another location on Shopify > Orders > Order ID > Change location. You can change the location of an order multiple times across different locations to fulfill the order at various locations during the fulfillment.

Shopify Custom Order Fulfillment

For items stocked at a Custom Fulfillment location within Shopify, you will not be able to send the order to this location and it must be dealt with in that custom fulfillment location, instead the order detail will be sent to the customer fulfillment provide via email, and you will need to manually mark the order as fulfilled within Shopify or SKUSavvy.

You can set an item to only be stocked at the custom fulfillment provider, in which case inventory will be reflected and depleted as you mark the order routed to that fulfillment provider as 'Fulfilled'

Manually Split the Order

The only different here is you will start fulfillling the order at one location then ship that order out. Shopify will update the order to reflect unfulfilled item quantities. You would later move the order to another location and go through the split fulfillment steps to fulfill the order.

3PL Third Party Fulfillment

If using a 3rd party logistics company you will likely have an app that connects to the 3PL software system which will enable a location on Shopify tracking inventory and orders to. If the 3PL is fulfilling a portion of the orders, and you are internally fulfilling another part of orders, you can coordinate the fulfillment of this split shipment, or simply split the order ahead of time so it is reflected back to your 3PL system. SKUSavvy will enable the split fulfillment to be available across multiple locations so you can move the order to different fulfillment centers or 3PL.

Use an Inventory & Fulfillment App LIke SKUSavvy

SKUSavvy or any number of the best Shopify inventory management apps can help split and manage fulfillments across different locations. SKUSavvy will enable you a one click reassignment of an order to a new warehouse. Using this method you don't even need to move into Shopify since you can partially fulfill the order in one location, move it to another, and continue fulfilling the order, and it will immediately be updated to the Shopify admin

How should you handle backorders on Shopify?

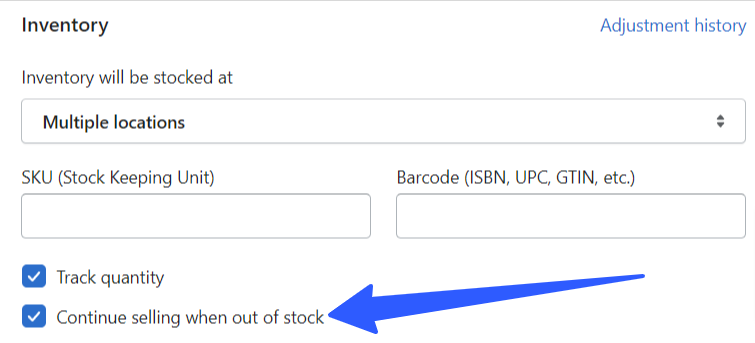

To accept backorders you need to set a product to continue being sold when out of stock. It is a setting that can be found on a single product and when checked, will enable you to sell this item even without any stock currently available across one or more locations

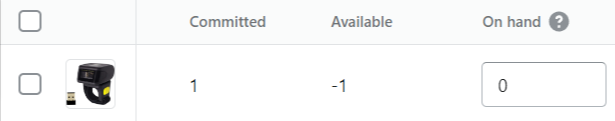

Backordered inventory will show as a negative on quantity on Shopify and will show up as a commited unit of inventory on SKUSavvy

Shopify Backorder Setting

SKUSavvy Backorder Setting

When you have inventory that's on backorder you can see that it will show as 1 committed unit (to the orders containing a backordered item) and a negative one for available quantity

You should place a PO for backordered items as soon as possible to avoid long fulfillment delays

How do you manage bin locations in Shopify?

The short answer is; you can't. There are no straightforward ways to set up bin locations within Shopify without using a Shopify app. Many have created workarounds that are very clunky and oftentimes break including setting up bins in the SKU, tags, and meta fields for bin locations, but these are all very limited

To utilize bin locations for inventory tracking in SHopify you need to get an inventory management app, see the best Shopify inventory management apps below

SKUSavvy offers the only all-in-one 3D visual bin location mapping to each warehouse. Use visual mapping to visualize a pick path, and be able to search your inventory on a map of the warehouse. Best of all, visual warehousing makes it faster to put-away and pick efficiently. Once connected with Shopify SKUSavvy pulls in all your warehouses, products, and inventory the provides an easy way to allocate that inventory to your newly created visual warehouse layout. Print bin labels on the fly.Get the best visual warehouse management system for Shopify

How should you replenish inventory across your warehouse locations?

This action is called cross-docking and its when you transfer some inventory from one warehouse to another warehouse. Within Shopify inventory management it will be called a transfer. But why can't you just move the inventory? The record of inventory needs to be accurate and cross-docking provides a method and process on each side of the transfer to prepare and ship as well as to check-in and receive so that proper inventory quantities are reduced and added to each warehouse location.

Steps to accurately replenish inventory with cross-docking and Shopify transfers

In your Shopify admin go to your Products > Transfers

Select the origin and destination locations, you must already have locations or custom fulfillment set up on your Shopify store

You can also select a vendor as the origin, this is the way to create a replica of a purchase order within Shopify

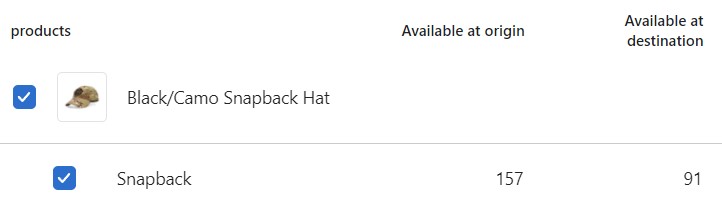

Add the products you want to transfer, during this process you can view available inventory quantities at both the transfer and destination

When a transfer is completed you will be able to confirm this inventory on the origin side, and accept them on the destination side

Simplify the transfer process in SKUSavvy

Shopify's method of cross-docking and managing transfers may work for stores with minimal needs and functionalities, however there is no true pick capability on the origin side, nor is there any capability to receive product on the receiving side. For stores doing high volume and potentially many transfers daily, SKUSavvy solves the challenge of inventory accuracy and the bin locations provided visually to pick transfers efficiently.

Go into a Warehouse > Transfers

Select the origin and destination locations to bring inventory from

Select the products and quantity to transfer then create the transfer

On the origin side, pick the items needed for transfer

On the destination side check-in the products and quantities sent from the origin warehouse

Quantities will be updated on the both sides of the transaction

Does Shopify help with reorder quantities on purchases?

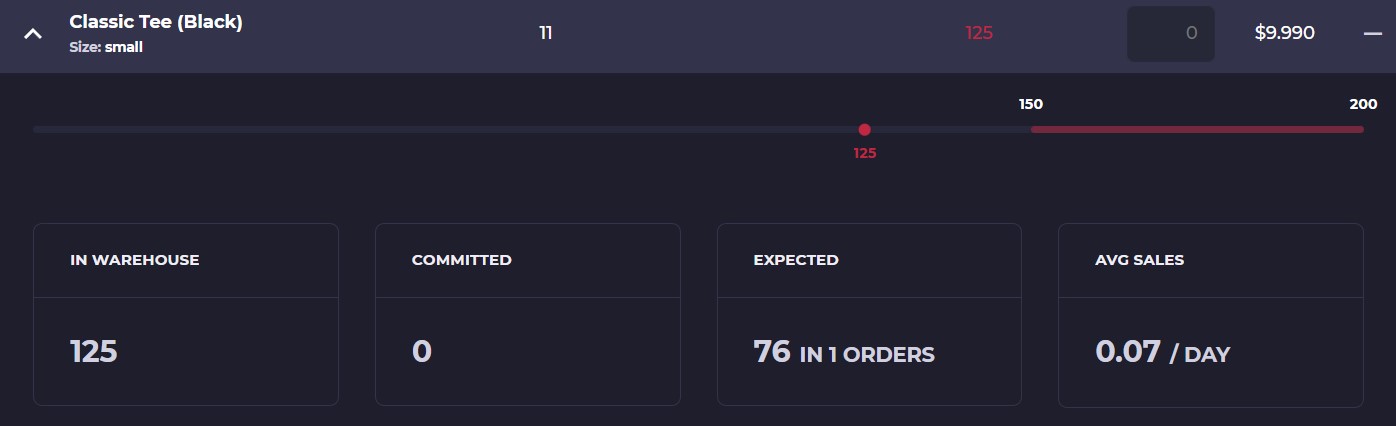

Currently you will be left to your own devices to determine reorder quantities within Shopify. This is another place you will likely need an app installed to get the benefit of reordering product so that you don't run out of stock. There are several very good apps out there that will help with reordering quantities, and you can utilize the features directly within SKUSavvy to enable this capability.

Shopify inventory management apps that help with reorderingSKUSavvy visual WMS for ShopifyFabrikator Shopify Forecasting ToolSyncware enterprise warehouse reporting platformShopify app store results for forecasting apps

What should you take into consideration when planning your reorder quantities for inventory?

Maintaining good inventory levels will be one of your most challenging problems with a fast growing storefront. Not only do you have unpredictable supply chains and shipping times, there are the issues of predicting demand and the wild swings in consumer preference. Below is a short list of considerations that any good forecasting tool should include:

Current sell-through rate: this is a measure of how fast the product is selling on a daily basis averaged over the lifetime sales of the product

Committed inventory value: as we talked about the committed inventory should be subtracted from our on hand inventory because this is already sold, so we want to purchase enough to make up for the already sold items

Expected inventory value: how many units of this one product are we going to be receiving, lets subtract this value from our forecasted amount since the expected inventory will increase our supply

Sales trends: Review sales data to understand the demand for each product and determine reorder quantities based on this information.

Lead time: Consider the time it takes to receive new inventory from suppliers and adjust reorder quantities accordingly.

Stockout cost: Assess the cost of being out of stock for a product and factor this into the reorder quantity decision.

Safety stock: Determine a safety stock level for each product to ensure that you have enough inventory to cover unexpected demand.

Ordering cost: Consider the cost of placing an order and the economies of scale for bulk orders.

Seasonal demand: Consider the impact of seasonal demand on your inventory levels and adjust reorder quantities accordingly.

Carrier capacity: Ensure that your inventory levels align with the capacity of your carriers to avoid overloading or underloading.

Supplier reliability: Consider the reliability of your suppliers and adjust reorder quantities accordingly to avoid stockouts.

Space constraints: Take into account storage constraints and the cost of storing inventory when determining reorder quantities.

How should I handle perishable items with Shopify inventory management?

This is another area that you may very well need some help from an app. You can use a similar method for expiration dates as described with bin locations, although meta fields and SKUs or variants set up with expiration dates will get messy quick. Using a system like SKUSavvy you will be able to turn on the perishable item flag and assign individual lot numbers and expiration dates to the items coming in as a normal purchase order, or as an ad-hoc adjustment with the lot number. With SKUSavvy FIFO methods are used to ensure your inventory is being picked oldest first. You can also set up lot tracking alerts that notify you at your decided time intervals about expiring product. Below are some considerations that will be taken into account within SKUSavvy to aid in dealing with perishable items in Shopify:

Track inventory levels: Keep track of the quantity of perishable items in your inventory. SKUSavvy will automatically update this information in Shopify to ensure accuracy

Set expiration dates: Set expiration dates for perishable items in Shopify and display this information to customers on your product pages. Every perishable item coming into the warehouse receives a lot/expiration date

Automated alerts: Set up automated alerts in SKUSavvy to notify you when an item's quantity reaches a low level, so that you can reorder before the item expires

First In, First Out (FIFO) method: Use the First In, First Out method to manage perishable items, which ensures that you sell the oldest items first, reducing the risk of waste. Lot/expiration date is shown during a visual pick batch on SKUSavvy with the oldest product highlighted

Prioritize sales: Prioritize the sale of perishable items to reduce waste, by offering discounts or promotions, or by selling items that are close to expiration first

Quality control: Implement a quality control process to ensure that all perishable items meet the required standards, and dispose of items that do not meet the standards to reduce waste

In conclusion, effective inventory management is crucial for the success of any online store. Shopify provides robust tools to help you manage your inventory, but it's important to understand the differences between committed, available, and on-hand inventory values and how to handle orders fulfilled across different locations. Additionally, backorders and bin locations should be considered in your inventory management strategy, along with rebalancing inventory across locations and determining reorder quantities. Finally, handling perishable items is an important aspect of inventory management, and Shopify provides features to help manage this effectively. By carefully considering each of these factors, you can use Shopify to manage your inventory and grow your online business successfully.

SKUSavvy is a comprehensive inventory management solution that solves all of the challenges outlined in the article, and effectively integrates with Shopify to maximize the efficiency of your warehouse. With SKUSavvy, you can easily track your inventory across multiple locations and manage your stock levels, ensuring that you never run out of stock or overstock. Additionally, SKUSavvy offers a visual warehouse layout, allowing you to quickly and easily see the location of each item in your warehouse. This helps you optimize your storage space and ensures that your items are easily accessible when you need them. By using SKUSavvy in conjunction with Shopify, you can streamline your inventory management processes, improve accuracy and efficiency, and ultimately grow your online business.